I didn't intend to build a RIMS when I decided to get into whole grain brewing. It just kind of evolved out of control. I bought 2 ten gallon Gott coolers, a Phil's Phalse bottom and a Phil's sparge arm to do infusion mashing. At the same time, I bought a boil kettle set up and an outdoor burner from Sabco. A pump wasn't even in my plans at this point, I wanted to use gravity as much as possible. As I sat down and started planing out how I was going to make this all work together smoothly, I quickly realized that I would have to have a set up that was way too tall. I decided to get a pump to make the transfer from the boil kettle to the carboys and hot liquor tank easier. At least this way, I could leave the boil kettle on ground level.

The frame was built, the pump installed, everything

was ready to go. Then I made the mistake of surfing the web and looking

at other people's RIMS. I was hooked. I based the heating element

control part of my RIMS on the setup built by Keith

Royster, who has been very helpful in answering my questions and working

with me on design problems. Thanks Keith. The rest of the design

is from my own imagination. I am not going to repeat all of the information

that Keith put on his page, he did an excelent job. I just want to

show the way I did it.

One

place I diverged a little from Keith's design is the heating element housing.

Instead of taking the element out from the top for cleaning and having

to leave the wires exposed to the environment and my accidental touch,

I used a compression fitting in the center of the element housing that

allows me to open the housing so I can clean the element after the mash.

The compression fitting on the output side of the element housing is unnecessary

and I removed it shortly after this picture was taken because it made the

return side too long. After talking to Keith about temperature overshoot,

he suggested moving the thermocouple to the output side of the heating

element vs. the input side as is shown in his original design. In

this picture, you can also see the PID (temperature controller)

that is mounted in the side of a plastic breaker switch box.

One

place I diverged a little from Keith's design is the heating element housing.

Instead of taking the element out from the top for cleaning and having

to leave the wires exposed to the environment and my accidental touch,

I used a compression fitting in the center of the element housing that

allows me to open the housing so I can clean the element after the mash.

The compression fitting on the output side of the element housing is unnecessary

and I removed it shortly after this picture was taken because it made the

return side too long. After talking to Keith about temperature overshoot,

he suggested moving the thermocouple to the output side of the heating

element vs. the input side as is shown in his original design. In

this picture, you can also see the PID (temperature controller)

that is mounted in the side of a plastic breaker switch box.

This

is a front view of the breaker switch box that houses all of the electronic

components. The power is run from an outlet on the house into a GFI

outlet on the right side of the breaker box. The pump and the PID

are plugged into the GFI outlet. I put switches in the circuit so

I can turn the pump and the PID on and off as needed without unplugging

them. Below the box, you can see the Solid State Relay(SSR) that

the PID uses to turn the heating element on and off.

This

is a front view of the breaker switch box that houses all of the electronic

components. The power is run from an outlet on the house into a GFI

outlet on the right side of the breaker box. The pump and the PID

are plugged into the GFI outlet. I put switches in the circuit so

I can turn the pump and the PID on and off as needed without unplugging

them. Below the box, you can see the Solid State Relay(SSR) that

the PID uses to turn the heating element on and off.

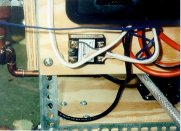

This

is a close up view of the SSR. The right side comes from the output

on the PID, polarity matters at this point so it is important the the wire

in the positive output is the same wire on the positive input. The

left side of the SSR controls the heating element. The polarity doesn't

matter on this side so you wire it just like a light switch, one of the

wires

is split and connected to both sides. The PID doesn't supply power

to the heating element, it just controls the switch. The heating

element gets its power from the same circuit as the PID.

This

is a close up view of the SSR. The right side comes from the output

on the PID, polarity matters at this point so it is important the the wire

in the positive output is the same wire on the positive input. The

left side of the SSR controls the heating element. The polarity doesn't

matter on this side so you wire it just like a light switch, one of the

wires

is split and connected to both sides. The PID doesn't supply power

to the heating element, it just controls the switch. The heating

element gets its power from the same circuit as the PID.

My

return manifold is a simple H shape. Nothing spectacular here, I

just tried to center the output in the four quadrants of the mash tun.

I had to drill a hole in the top of the lid so I could adjust the height

of the manifold depending on how much grain is in the mash tun. This

is the only permanent modification that I had to make to the Gott coolers.

My

return manifold is a simple H shape. Nothing spectacular here, I

just tried to center the output in the four quadrants of the mash tun.

I had to drill a hole in the top of the lid so I could adjust the height

of the manifold depending on how much grain is in the mash tun. This

is the only permanent modification that I had to make to the Gott coolers.

I

started out using a Phil's Phalse bottom but couldn't get it to work.

I was afraid that the thick pad included with the Phalse Bottom would restrict

the liquid flow and I couldn't get it to stop floating without the pad.

The black rubber gasket fits the 1/2" braided hose very snug. I bought

the gasket at the hardware store and then used a little dish soap to lubricate

it enough to feed the hose into the bucket. The manifold has small

holes drilled in the bottom to allow liquid to flow but keep grain from

getting in. It fits snug to the sides of the cooler and stays in

place quite nicely.

I

started out using a Phil's Phalse bottom but couldn't get it to work.

I was afraid that the thick pad included with the Phalse Bottom would restrict

the liquid flow and I couldn't get it to stop floating without the pad.

The black rubber gasket fits the 1/2" braided hose very snug. I bought

the gasket at the hardware store and then used a little dish soap to lubricate

it enough to feed the hose into the bucket. The manifold has small

holes drilled in the bottom to allow liquid to flow but keep grain from

getting in. It fits snug to the sides of the cooler and stays in

place quite nicely.

The

pump is the heart of the system. I got mine from Moving

Brews, they were very knowledgeable and helpful, I highly recommend

them. The far side of the picture is where the input from the mash

tun and boil kettle comes in. The near side is where output is directed

to the heating element and to a hose that I can use to fill the hot liquor

tank, carboys and the boil kettle during sparging.

The

pump is the heart of the system. I got mine from Moving

Brews, they were very knowledgeable and helpful, I highly recommend

them. The far side of the picture is where the input from the mash

tun and boil kettle comes in. The near side is where output is directed

to the heating element and to a hose that I can use to fill the hot liquor

tank, carboys and the boil kettle during sparging.

Here,

I have the system set up for sparging. I found it easier and faster

to fill the hot liquor tank on the ground and lift it to the top shelf

of the rack. The pump will fill the cooler without having to take

it down but it takes quite a while. Gravity drives the flow of water

to the Phil's Sparge Arm and causes the arm to spin and evenly distribute

water over the grain bed. There is an in-line valve below the blue

hose that I can use to adjust the rate of flow into the mash. I use

one of the ball valves to control the flow into the boil kettle.

Here,

I have the system set up for sparging. I found it easier and faster

to fill the hot liquor tank on the ground and lift it to the top shelf

of the rack. The pump will fill the cooler without having to take

it down but it takes quite a while. Gravity drives the flow of water

to the Phil's Sparge Arm and causes the arm to spin and evenly distribute

water over the grain bed. There is an in-line valve below the blue

hose that I can use to adjust the rate of flow into the mash. I use

one of the ball valves to control the flow into the boil kettle.